The Price of Strength: Why All TMT Bars Aren’t Created Equal

When building a home or a massive bridge, one of the most critical components is the TMT bar, which forms the backbone of any concrete structure. But have you ever wondered why some TMT bars from branded companies cost significantly more than others? The answer lies in the steelmaking process itself: Primary vs. Secondary.

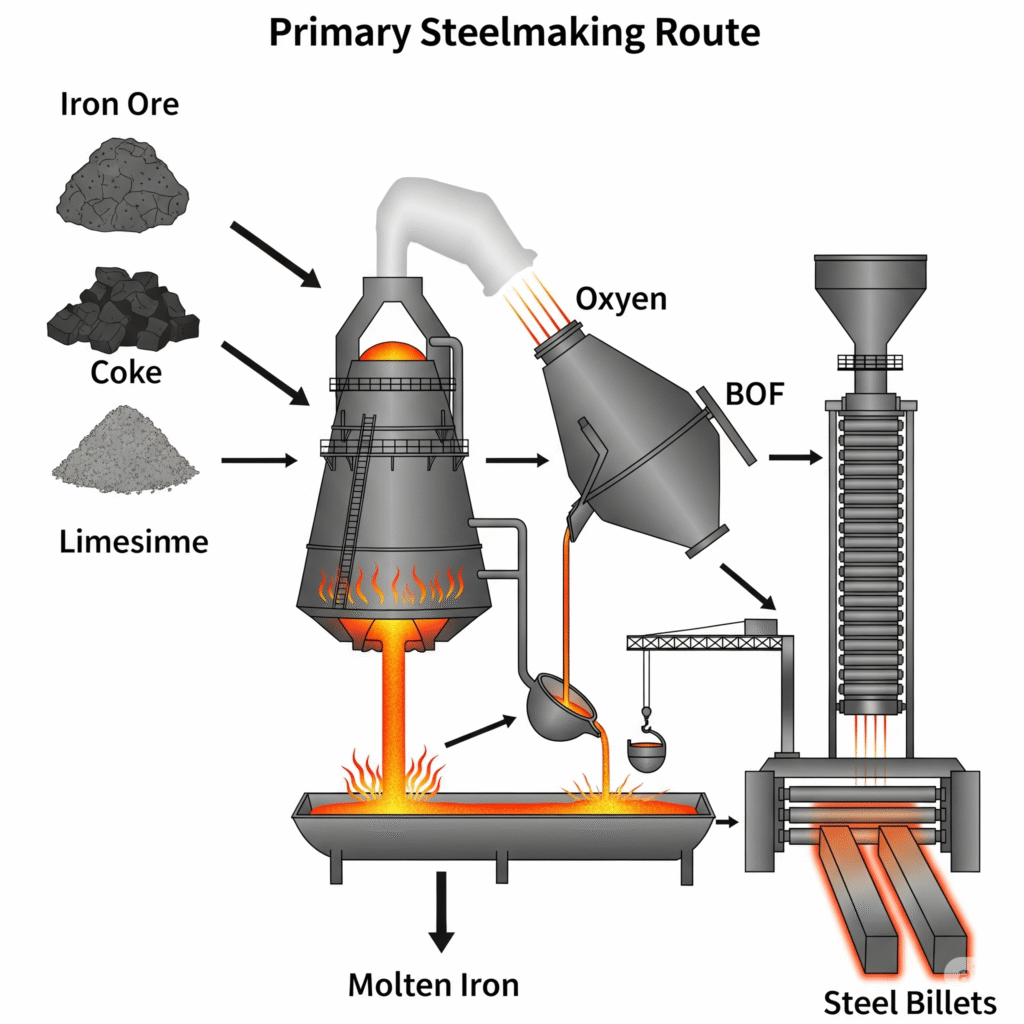

Primary Steel Making: The Path to Purity

Primary steel making is the process where steel is produced from scratch using raw materials like iron ore. It’s a longer, more controlled method designed to produce the purest possible steel.

The Process: This process starts by melting iron ore in a Blast Furnace (BF) to create hot metal or pig iron. This molten metal is then refined in a Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF), where oxygen is used to remove impurities like carbon, sulfur, and phosphorus.

After this, the steel undergoes Ladle Refining (LRF), a crucial step that allows for precise control of the steel’s chemical composition. This is where harmful impurities like phosphorus and sulfur are meticulously brought down to minimal levels. Finally, the refined steel is cast into billets and then rolled into TMT bars.

The biggest advantage of this method is the control over the raw material, which ensures a very low level of impurities, particularly phosphorus. As per the IS1786 standard for Fe500D grade, the maximum phosphorus content should not exceed 0.040%. Primary steel manufacturers can consistently maintain levels well below this, ensuring a superior quality product.

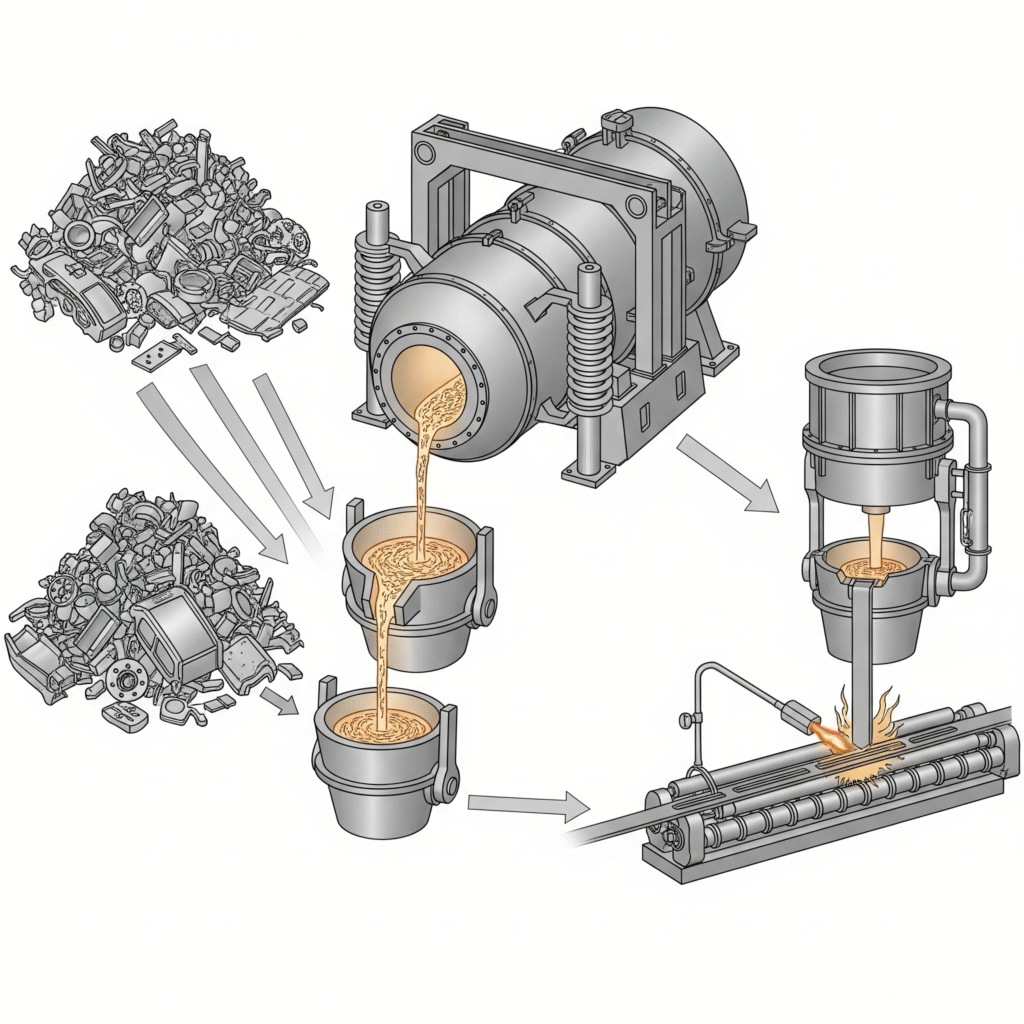

Secondary Steel Making: The Risk of Impurities

Secondary steel making uses scrap steel or sponge iron as its main raw material. This process is faster and more cost-effective but has a significant drawback: it’s much harder to control the purity of the final product.

The Process: In this method, scrap steel is melted in an Induction Furnace (IF). The molten steel is then directly cast and rolled into TMT bars. Unlike the primary process, secondary steel making often lacks the advanced refining stages like LRF. This means that impurities present in the scrap, especially phosphorus, don’t get fully removed.

While some companies use sponge iron, it’s often not enough to effectively refine the phosphorus level, which can already be high in the raw material. Consequently, phosphorus levels in secondary steel can be uncontrolled, sometimes ranging from 0.070% to 0.10%, which is well above the IS1786 standard of 0.040%.

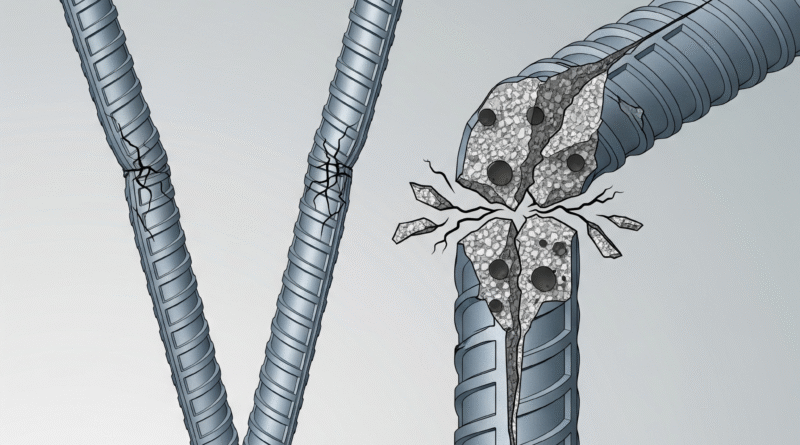

The Phosphorus Problem: When Steel Becomes Brittle

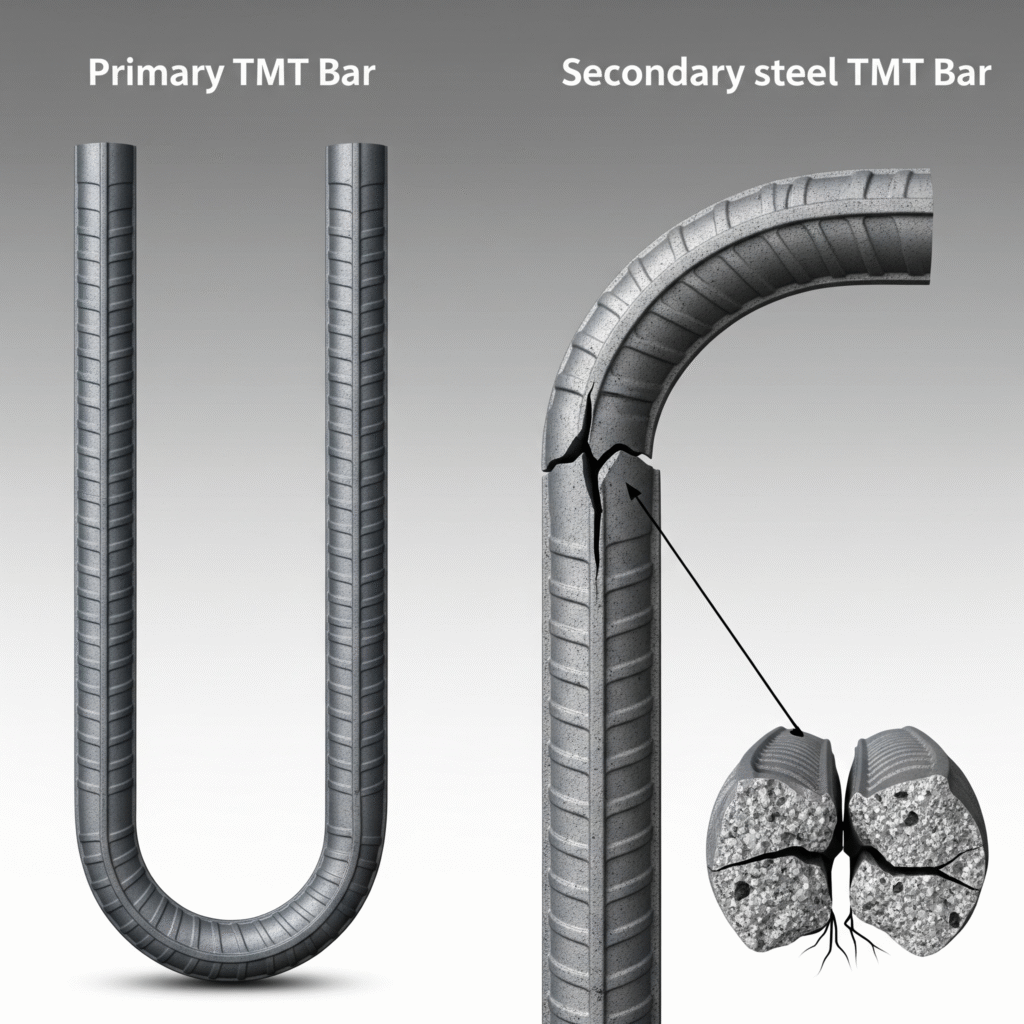

High levels of phosphorus in TMT bars are extremely detrimental to steel quality. It makes the steel brittle, significantly increasing the risk of the bar breaking while being bent. This leads to issues with bending, a compromised yield stress, and a general lack of durability.

This is precisely why TMT bars from primary manufacturers like SAIL, JSW Steel, Tata Steel, JSPL, and VIZAG Steel are more expensive. Their rigorous, multi-stage process ensures low phosphorus content, resulting in bars that are flexible, strong, and highly durable.

On the other hand, secondary steel manufacturers like Shyam Steel, GK Steel, Goel Steel, and Metaroll often have more affordable TMT bars. While these can be suitable for smaller projects or residential construction, they may not be ideal for large-scale, high-stakes projects.

For critical government projects like flyovers, bridges, and other safety-related infrastructure, it is crucial to use TMT bars made from primary steel. The government should strictly enforce this requirement to ensure the long-term safety and structural integrity of these essential constructions. By using strictly high-quality, primary-made steel, the chances of structural failure and accidents can be significantly reduced, protecting lives and investments for years to come.

what’s your opinion comment below!